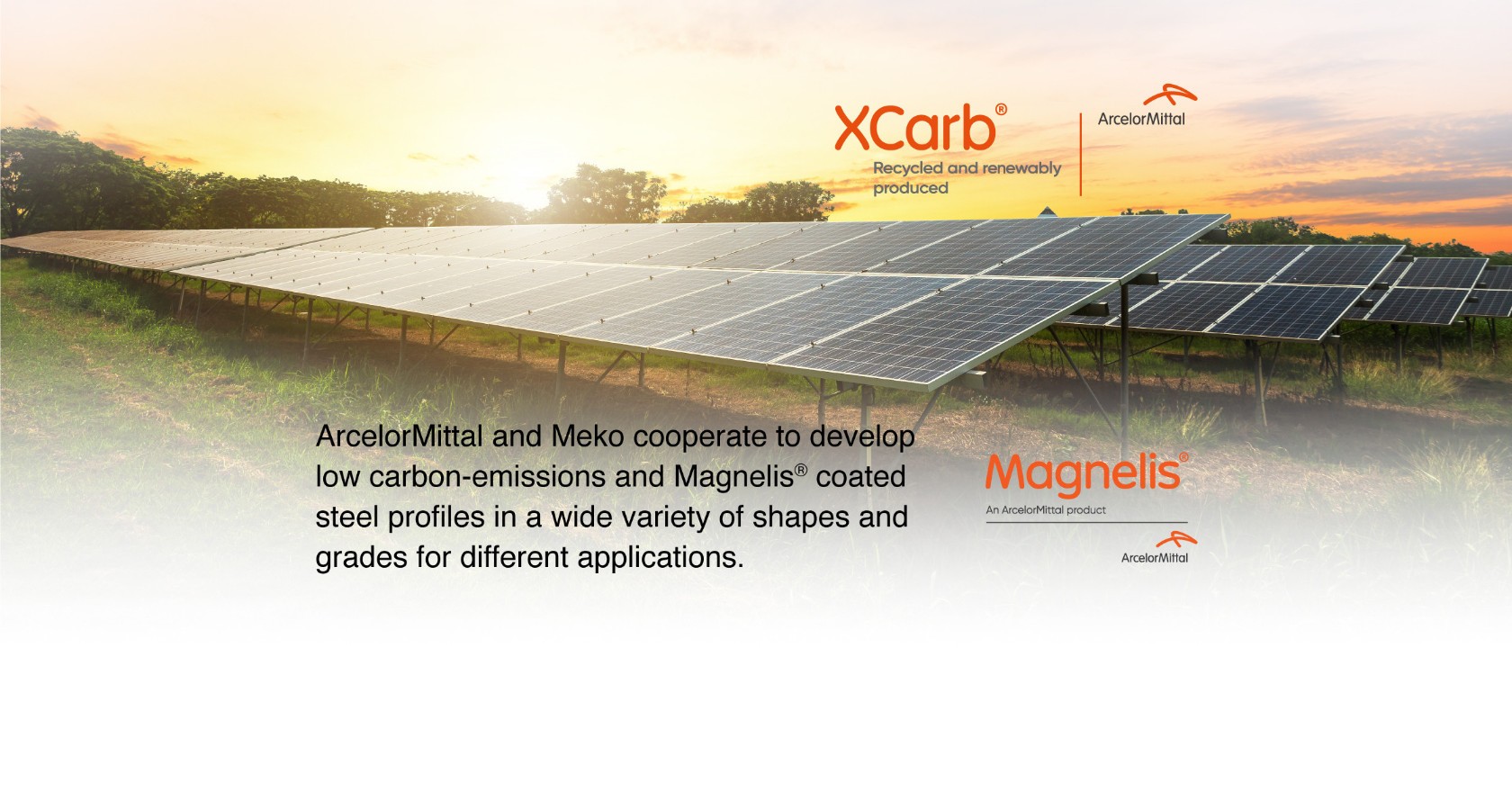

Solar Energy

Systems Profiles

PRODUCTS

Civil Works & Steel

Constructions Profiles

PRODUCTS

Profiles for

Agriculture and Greenhouse

PRODUCTS

Automotive Profiles

PRODUCTS

Standard Tubes and Profiles

PRODUCTS

Specials Profiles

PRODUCTS

Profiles for

Electric & Electronics

PRODUCTS

HVAC Profiles

PRODUCTS

Stainless Steel Profiles

PRODUCTS

Solar Energy Ground Mounting Systems

PRODUCTS

Solar Energy Roof Mounting Systems

PRODUCTS

Standard Tubes and Profiles

Special Profiles

Automotive Profiles

Solar Energy Systems Profiles

Solar Energy Ground Mounting Systems

Solar Energy Roof Mounting Systems

Civil Works & Steel Constructions

Profiles for Agriculture and Greenhouse

Profiles for Electric & Electronics

HVAC Profiles

Stainless Steel Profiles

To visit us

GET DIRECTIONS

The harshest environments need the toughest skin protection.

The best corrosion resistance performance; up to 3 times better than galvanized steel.

The best suited protection to withstand harshest environments

The most cost-effective alternative to the hot-dip galvanized process.

WE BELIEVE IN THE SANCTITY OF PRODUCTION!

MEKO Metal has started its production operations in 1969 in 10.000 sqmtr area and continues its operations under KMC Group since 2011 by collaborating their unique commercial & technical production knowledge and experiences in 100.000 sqmtr area in Torbalı-Izmir, with annual production capacity of 150.000 tons by following the worldwide technological developments.

ABOUT US

What makes meko metal special?

Roll-forming provides maximum sensitivity in bending, punching and slot axes.

Roll forming presents various shapes with its high number of stations which can compete with your dreams.

Roll-forming offers volume advantage mobility and cost efficiency with the advantage of high number of stations and our ability to form the sheet that has high yield strength and low thickness.

Roll-forming brings significant price advantage in comparison with aluminum due to crucial parts of your production that needs to be aluminum can also be replaced by roll-formed steels.

Roll-forming gives better length, volume and sensitivity comparing with laser punch and press brake. Longest press brake is 8m long and tandem ones doesn’t provide sensitivity as roll-forming.

Roll-forming ensures time and cost advantages by eliminating processes such as punching, blowing, notching and welding.